How Do You Describe The Working of a Variable Speed Air Compressor?

Whether an owner of a house is looking for the best vital way to wash your courtyard or a manager of a warehouse seeking to step up the production, air compressors are a practicable approach to perform multiple projects.

The original air compressor was quickly improved upon by inventors, who also developed other tools to carry out the same function. Air compressors’ initial capabilities were constrained. However, as the years passed, air compressor technology continued to advance, and today’s numerous machines have a variety of applications.

For various industries and many residences variable speed air compressor can be used. You gain more than simply a product when you work with WEMANUO for your compressor needs. You also acquire a dependable ally who will support your company.

How Is a Variable Speed Screw Compressor Made?

There are specific steps required for manufacturing a variable-speed air compressor;

Cutting

The metal sheets are cut into the necessary shapes and sizes using high-precision laser-cutting equipment.

Forming

They mold the metal sheets into the necessary shape using sophisticated bending machinery, guaranteeing exact and precise measurements.

Drying & Painting

The metal sheets are painted with premium paint after they have been cut and molded, and the paint is dried in a controlled environment to produce a faultless surface.

Assembling

The motor, variable frequency drive, and oil and gas separator are all carefully put together, making sure that every component fits together seamlessly.

Whole Assembling

The assembled elements are integrated into the compressor to make sure everything functions as a whole.

Control of Quality

Before being dispatched, every compressor goes through a stringent testing and inspection process to make sure it lives up to its high expectations for performance and quality.

Packing

The compressors are packed with high-quality materials to keep them safe during delivery and guarantee that they reach their destination in fine shape.

Shipment

They collaborate with dependable logistics partners to make sure the compressors are delivered on schedule, with full tracking and insurance coverage.

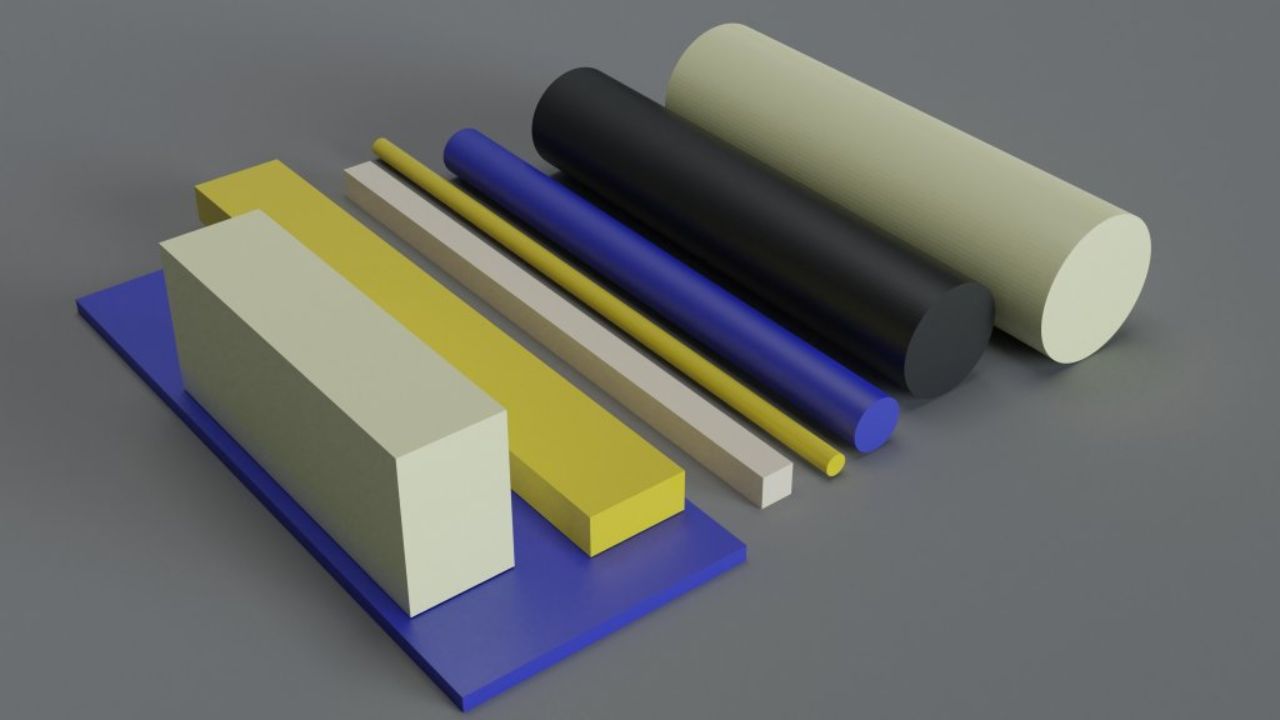

Multiple Sorts of Air Compressors

Different mechanical elements are used by air compressors to raise air pressure and lower the volume of trapped air. You should think about the various varieties when selecting an air compressor to make an informed decision. Here are the various air compressors that may be found online.

Rotary Screw Compressor

Two screws are used in rotary screw compressors to limit the amount of trapped air, with the meshed twin spiral screws maximizing air payout and intake. Rotary screws have a larger flow rate than some other air compressors and can be employed in heavy-duty applications where precise air control is required. These compressors are dependable for a variety of tasks due to their exceptional durability.

Reciprocating Piston

A crankshaft is used in reciprocating piston air compressors to rotate the piston back and forth, decreasing the volume of air. The tank is filled with compressed air as it is pushed into the tank by the extending piston. These compressors don’t need a lot of maintenance and are portable.

Scroll Compressor

Industries that require changing levels of intensity are great candidates for scroll compressors. These compressors lower the amount of air by moving a spiral-shaped scroll in a circular motion. These compressors are a popular option because they are typically quieter and have a long lifespan.

Oil-Free & Oil Flooded

When buying any air compressor, here are two sorts of oil pumps to take into consideration: flooded with oil and oil-free. Oil is used to lubricate walls and bearings in oil-flooded air compressors, and the oil can occasionally splash. Due to their design, these systems can be noisy and generate a lot of heat even though they are frequently quite durable.

Last Wording

Pneumatic gadgets called air compressors transform an energy source into pressurized energy that can be used. Most latest and modern time air compressors have a tank where the air is kept to generate the extra pressure. When it’s time to use it, the pressurized air is stored in the tank and discharged as a forceful stream. Hope that after reading out this article you will get more details about the variable speed air compressor.