How to Make CNC Machined Parts: A CNC Machining Process

When talking about manufacturing, most people think of big factories churning out mass-produced goods. However, there’s another kind of manufacturing that’s more attainable for smaller shops and home hobbyists. CNC machining is a type of manufacturing that uses computer numerical control to create milled parts from solid material. It’s an ideal process for those looking to make their own custom parts or have greater control over the quality of their final product. Read on to learn more about how to make CNC machined parts, as well as other tips and resources you can use to get started.

Benefits of CNC Machining

- Better Control over Quality - One of the biggest benefits of using CNC machining is the increased control over quality. While some manual processes allow for some control over quality, it’s difficult to match the precise accuracy of a digital machine. With a digital machine, you’re able to completely remove material if the dimensions are off, which allows you to inspect the part and make adjustments before beginning the process again.

- Easier Inspection and Debugging of CAD Models - Another benefit of CNC machining is the ability to inspect and debug CAD models. Because the digital models are so precise, you have the ability to inspect them closely to ensure there are no issues such as unwanted holes or marks on the workpiece. You also have the ability to check the dimensions of the digital model to ensure the dimensions are exact and don’t need adjustments before starting the machining process.

- Reduced Tooling Costs - Since CNC machining is a type of manufacturing that doesn’t require physical tools, it’s also a more cost-effective process than traditional manufacturing methods. That’s because it doesn’t require any new machinery or tooling, allowing you to start quickly with minimal out-of-pocket expenses. That saves money and time down the road as you won’t have to purchase new machinery or tooling as you grow your business.

How to Make CNC Machined Parts

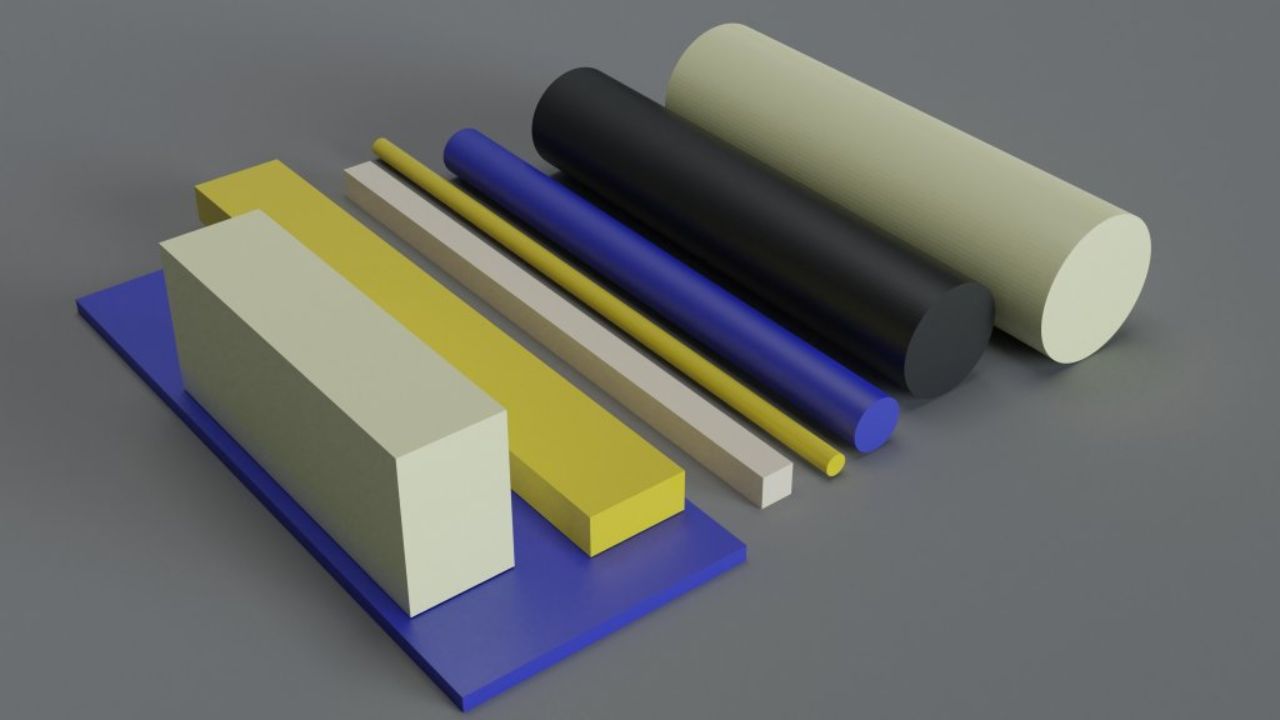

The final product from CNC machining can be virtually any shape or size, depending on the type of machine you use. Once you’ve created your digital model, it’s time to decide the type of machine you’ll use. Some general types of CNC machines are discussed below, but there are many others available for specific applications.

- Turning Machines - Turning or extruding machines are the most common type, creating parts out of material such as steel and aluminum. They are also often referred to as CNC lathes or CNC mills.

- Milling Machines - Milling machines use a cutting tool to create parts out of wood, plastics, and other softer materials.

- Drilling Machines - These CNC machines are designed to create holes, slots, and other features in materials using a rotary tool.

Tips for Successful CNC Machining

- Know Your CAD Model - A key part of any CNC machining process is knowing how to inspect and debug your CAD model. Inspect the model by checking the dimensions, making sure there are no issues with the model, and looking for any issues with the surface that could cause the part to wear out. Debugging your model means making any necessary adjustments to the dimensions before starting the machining process.

- Remove Unwanted Material - In order to ensure a precise result, it’s important to remove any material from the part that is unnecessary. For example, when milling a cylinder, you want to remove any material between the base and the top so the part will have the desired height. Those details can be adjusted during the machining process so you don’t have to take a break for a more tedious task.

- Add Clearance for Moving Parts - CNC machining can create parts with tight tolerances, but those parts will wear out faster if they’re too tight. To help extend the lifetime of the part, add a small amount of clearance for moving parts such as standard shafts used in robotics.

- Use High-Quality Materials - When choosing the type of material to use, keep in mind that there’s a difference between high-quality and low-cost materials. A higher-quality material will last longer and require less maintenance, while a lower-cost material may look better but wear out more quickly.

Conclusion

CNC machining is an ideal way to create custom parts and components for a variety of uses. It offers greater control over quality, has reduced tooling and production costs over other manufacturing methods, and can be used to create models from virtually any shape or size. Whether you’re interested in prototyping new ideas or making final production parts, CNC machining is an ideal method for producing high-quality components.