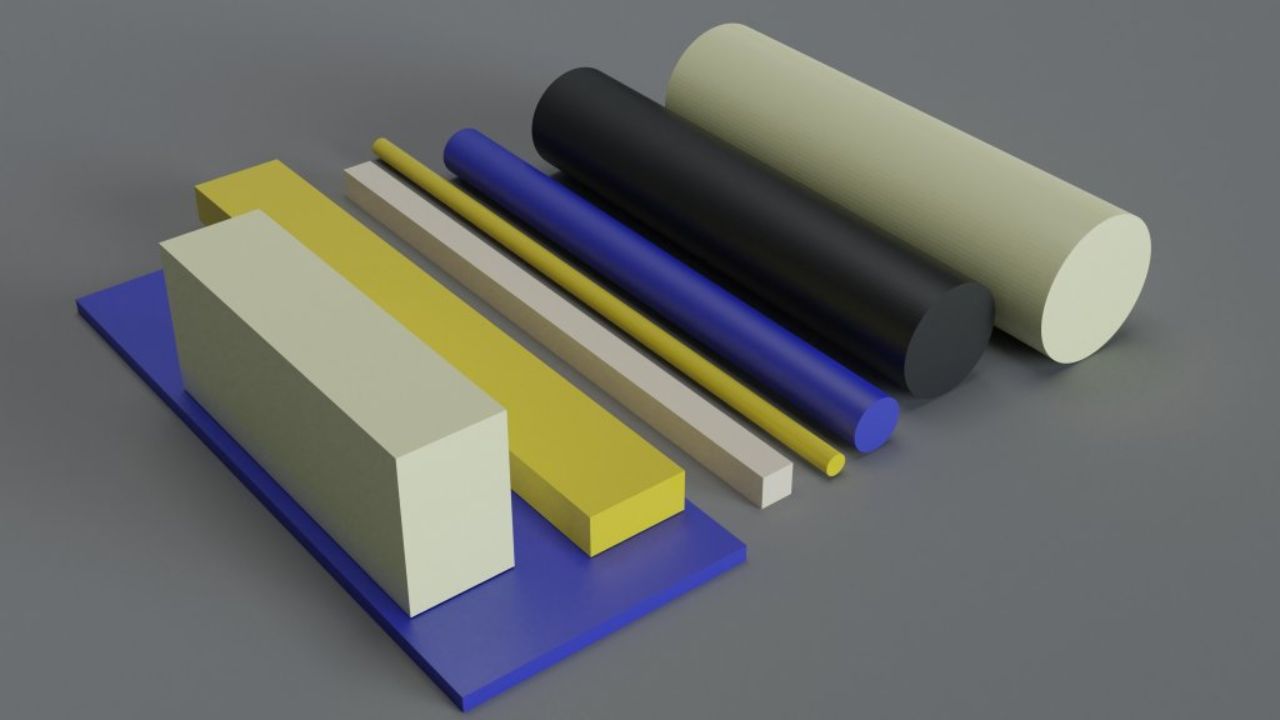

Tips for Working with UHMWPE Sheets, Blocks, and Pipes

Ultra High Molecular Weight Polyethylene, also referred to as UHMWPE, is a very diverse and high-performance product that has broad use in a variety of industries, such as manufacturing or even in the medical sector. It has remarkable wear resistance, low friction, and chemical stability, which makes it appealing to engineers and fabricators. However, in work with UHMWPE sheets, blocks, and pipes, there is specific knowledge that is necessary to guarantee the highest performance and the longest possible life. The tips that will be given below will guide the professionals dealing with uhmwpe plastic in a practical manner.

Tip 1: Choose the Correct UHMWPE Grade

The key to working with UHMWPE is to first of all choose the appropriate grade to be used in the application. UHMWPE sheets, blocks, and pipes are offered in various formulations, with each of them providing different trade-offs between wear resistance, impact strength, and chemical stability. Highly abrasive applications, like industry, and those that demand certified contamination-safe materials, like those involved in food processing or medical applications. The selection of the right grade will guarantee performance and reduce premature failure in the long term.

Tip 2: Use Sharp and Appropriate Cutting Tools

UHMWPE is hard and strong, and cutting it when using the wrong tools may be difficult. Cutting and sharp blades that are used on plastics assist in creating smooth edges and ensuring that the material is not torn. Sharp tools may produce a lot of heat and melt instead of cutting. Keeping tooling clean and sharp is also a major source of enhanced accuracy and finish.

Tip 3: Control Heat during Machining

Handling of the UHMWPE sheets or blocks requires a lot of heat when machining. The material can be distorted due to too much friction because it has a lower melting point than metals. Reduced cutting rates, constant feed rates, and occasionally halting enable heat to escape. Dimensional stability can be maintained in certain situations using air cooling or light lubrication.

Tip 4: Secure Material Properly Before Processing

UHMWPE is generally prone to plasticity when pressure is applied, particularly on thinner sheets or longer pipes. It is more beneficial to fix the material in place and then cut, drill, or rout before the material becomes vibrated and imprecise. The appropriate clamping also holds against the tool chatter, which may create an irregular surface or inappropriate dimensions when fabricating.

Tip 5: Use Plastic-Specific Drill Bits

The process of drilling UHMWPE cannot be done with standard drill bits; rather, plastic-specific drill bits are used. Such bits assist in the dissipation of heat and the making of fine holes without melting the surrounding material. Slow pressure drilling is more effective than pushy force, particularly as the block or pipe being intruded becomes thicker.

Tip 6: Allow For Thermal Expansion

UHMWPE has the tendency to expand and contract, unlike many traditional materials. This characteristic should be considered by designers and fabricators in installing the sheets, blocks or pipes within an assembly. Proper clearance will eliminate the possibilities of warping, stress accumulation, or cracking in a situation where the material is subjected to changes in temperature during operation.

Tip 7: Clean Surfaces before Joining

Surface cleanliness is required when the UHMWPE components require assembling or bonding. Dust, grease or debris may minimize the quality of contact and compromise the joints. Even though UHMWPE can be hard to bond using conventional adhesives, it can be enhanced with appropriate surface preparation in cases when mechanical fastening or special bonding techniques are applied.

Tip 8: Store Material Correctly Before Use

Adequate storage is significant in maintaining the quality of UHMWPE. Sheets, blocks and pipes are to be stored as flat as possible and not in direct light or under extreme temperatures. The lack of proper storage conditions may lead to bending or deterioration of surfaces, which makes it more challenging to fabricate the product and shortens its life.

Tip 9: Work With Experienced Suppliers

The collaboration with a better-educated supplier of UHMWPE eases the manufacturing procedure. Skilled manufacturers offer advice on material choice, machining suggestions and availability of customization. This knowledge can be used to make sure that UHMWPE products are specific to the performance requirements, and waste and errors are minimized during the production process.

Conclusion

UHMWPE sheets, blocks, and pipes are characterized by excellent durability, wear resistance, and versatility across a large environment of industries. Nevertheless, the best outcomes are possible in the case of knowledge of the specifics of the material and its delicacy during fabrication. When using correct machining procedures, heat and expansion control, and cooperation with trusted suppliers, engineers will be able to make the most of the benefits of UHMWPE and create parts that can provide stable performance in very aggressive conditions.