In the wood processing industry, equipment lifespan is a crucial consideration for businesses looking to optimize their operations and minimize costs. Wood shredders and grinders are vital machines in this industry, and the wear parts they use to play a significant role in extending equipment lifespan. In this article, we will delve into the importance of wood shredder and grinder wear parts and how they contribute to extending the lifespan of these valuable machines. Welcome to visit the JYF Machinery to learn more!

Protection Against Wear and Tear:

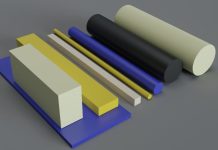

Wood shredder and grinder wear parts, such as blades, hammers, and screens, act as the first line of defense against wear and tear caused by the abrasive nature of wood materials. By withstanding the constant impact, friction, and abrasion, these wear parts protect the critical components of the machine, including the cutting mechanism, motor, and bearings. By minimizing wear and tear, wear parts help extend the overall lifespan of the equipment.

Optimal Performance and Efficiency:

High-quality wear parts are designed to provide optimal performance and efficiency. Sharp and properly maintained blades ensure clean and efficient cutting, while well-designed hammers and screens enhance the grinding process. When the wear parts are in excellent condition, the wood shredder and grinder machines operate at their peak efficiency, resulting in improved production rates and reduced energy consumption. This optimized performance contributes to the longevity of the equipment.

Reduction in Downtime:

Regular wear parts replacements and maintenance can lead to significant downtime in wood processing operations. By investing in high-quality wear parts, businesses can minimize downtime and maximize productivity. Durable wear parts require fewer replacements and repairs, allowing the machines to operate for more extended periods without interruptions. Reduced downtime translates to increased production output, leading to improved overall profitability.

Cost Savings:

Extending the lifespan of wood shredders and grinders through proper wear parts selection and maintenance offers significant cost savings for businesses. When equipment lasts longer, there is no need for frequent capital investments in new machinery. Additionally, by reducing downtime and the frequency of wear parts replacements, businesses can save on labor costs and expenses associated with purchasing replacement parts. These cost savings contribute to the long-term financial health of the business.

Customization for Specific Applications:

Different wood processing applications require specific wear parts configurations. High-quality wear parts can be customized to meet the specific needs of each application. Whether it is processing hardwoods, softwoods, or specialized materials, customized wear parts ensure optimal performance and longevity. By choosing wear parts that are tailored to the specific requirements of the application, businesses can achieve better results and prolong the lifespan of their equipment.

Regular Maintenance and Inspections:

Proper maintenance and regular inspections of wear parts are essential for extending the lifespan of wood shredders and grinders. Implementing a maintenance schedule that includes routine inspections, cleaning, and lubrication of wear parts helps identify potential issues early on and prevents more significant problems from arising. By staying proactive in wear parts maintenance, businesses can maximize the lifespan of their equipment and avoid costly repairs or replacements.

Conclusion:

Understanding the importance of wood shredder and grinder wear parts is crucial for businesses in the wood processing industry. These wear parts not only protect the equipment from wear and tear but also contribute to optimal performance, reduced downtime, and cost savings. By investing in high-quality wear parts, customizing them for specific applications, and implementing regular maintenance practices, businesses can extend the lifespan of their wood shredders and grinders, leading to improved productivity, profitability, and long-term success.