Why do we use CNC machining acrylics?

Acrylics are widely used in CNC machining because of their excellent physical and chemical parameters. It is cheap, lightweight, and easy to mould. It can be moulded in many ways, like CNC machining, casting, injection moulding, and thermoforming. Injection moulding is a simple and easy process to mould acrylics. Most Optical lenses, automotive lamps, and transparent tubes are manufactured by this method. But, the CNC machining acrylic method is specially used to make prototypes and custom parts. Some of the distinguishing features of acrylics are given below.

- Acrylic is the most widely used plastic with good processability. It is five times stronger and less dense than glass. It possesses excellent shock-absorbing power and is not shattered to pieces even in a powerful collision. These characteristics of acrylic make it durable and highly tensile.

- It has high transparency of 92%.

- It also has a good surface hardness, making it suitable for processing at high temperatures.

- Acrylic has excellent weather resistance. Intense UV rays cannot alter its quality compared to other fragile plastics that turn yellow in the open air.

- It is chemically stable and resistant to toxic compounds.

- The spraying and printing of the acrylic give it a beautiful surface gloss. LED lights, advertising banners, car lights, etc., are made of acrylic for a shiny appearance.

Which acrylic is better for CNC machining?

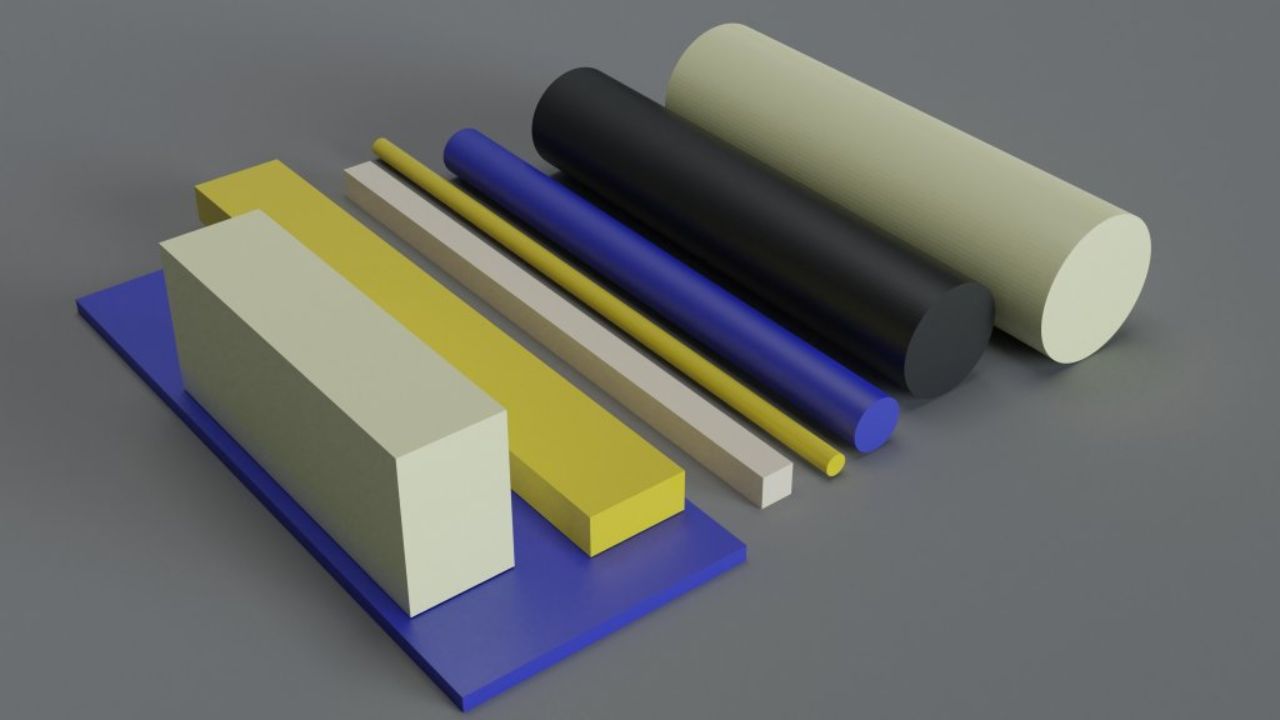

Most of the acrylic is synthesized by two methods that are given below:

- Extrusion

- Casting

Extrusion method is used to manufacture acrylic sheets, while casting method is used to make both acrylic sheets and blanks. Extruded acrylics are more brittle and can break easily due to high residual tension. In contrast, cast acrylics are more durable and chemical resistant, which makes them suitable for CNC machining.

Clamping of acrylics:

Clamping of acrylics is a very crucial process to ensure their precision and dimensional accuracy. Simple clamps are used to cut small pieces of acrylic. Large acrylic sheets require great care and inspection for their clamping.

How to ensure precise CNC machining acrylics?

You need to take a few guidelines and precautions in CNC machining acrylics. Some of them are given below:

Feed rate:

A stable feed rate is a primary requirement of any CNC machining acrylics with an RPM of about 15000-18000. It continuously moves the CNC milling machine and prevents heat generation due to resistance production. The machine operator decides the optimum feed rate for CNC machining acrylics. A low feed rate will lead to the re-welding of the acrylics, which can destroy their surface finish.

Right machinery:

Special clamping tools and equipment are required to maintain the precision and tolerance of the acrylics. Keep the drill machine at 60 degrees for accurate chip removal.

Cooling mechanism:

Great care and attention are required for the cooling mechanism of acrylics. Use the low temperature in the CNC machining of the acrylics because of their low melting point. Low temperature also makes chip removal easier. Most acrylic sheets are cooled down before processing in the CNC machines. Make sure that the cooling material does not chemically react with the acrylics.